The metal casting industry is constantly evolving, pushed via the demand for bigger precision, enhanced high quality, and minimized defects. On this landscape, the tension casting equipment performs an important function. having said that, for the most demanding applications, a specialized form of casting machine is needed: the vacuum tension casting equipment. this text explores the exclusive benefits of these machines, focusing on how they increase the precision and top quality of metal casting, specifically for treasured metals like gold and platinum.

Table of contents:

The Advantages of utilizing Vacuum stress Casting equipment for top-good quality effects

How Vacuum stress Casting boosts the precision of Gold, Platinum, along with other Metals

Why Vacuum tension Casting is important for High-Precision Industries

some great benefits of utilizing Vacuum Pressure Casting equipment for prime-Quality success

Vacuum force casting devices offer you an important breakthrough in comparison to traditional casting techniques. The Main advantage lies during the elimination of air pockets and fuel porosity within the casting. By doing the casting system beneath a vacuum, the molten steel is allowed to circulation far more freely and completely fill the mold cavity. This leads to denser, much better castings with fewer internal defects. Also, the application of stress in the course of the solidification stage helps you to even more consolidate the metal, reducing shrinkage and bettering the overall high-quality. This makes vacuum force casting ideal for developing intricate and complex styles the place even the smallest imperfections can compromise the operation or aesthetic attractiveness of the final merchandise.

How Vacuum Pressure Casting boosts the Accuracy of Gold, Platinum, together with other Metals

The high worth and exclusive properties of important metals like gold and platinum necessitate Excellent casting precision. Vacuum gold casting device know-how is particularly intended to meet up with these demanding prerequisites. The vacuum natural environment not just prevents oxidation of your molten metallic but also ensures a clear and steady casting system. This is especially vital for gold, which can easily tarnish or develop surface area defects if exposed to air for the duration of casting. What's more, the controlled force used throughout solidification encourages uniform grain framework and minimizes the chance of cracking or distortion. This leads to castings that are dimensionally exact, have great surface complete, and retain the desired mechanical Attributes.

Why Vacuum Pressure Casting is Essential for significant-Precision Industries

significant-precision industries, which include aerospace, professional medical machine manufacturing, and significant-close jewellery output, rely upon vacuum stress casting to attain the stringent good quality expectations needed for his or her apps. a chance to deliver castings with limited tolerances, minimum defects, and dependable material Houses is paramount in these sectors. For example, during the aerospace industry, vacuum force Solid elements are Employed in significant motor areas where by trustworthiness and performance are non-negotiable. equally, in professional medical machine producing, vacuum strain casting ensures the biocompatibility and structural integrity of implants. the advantages extend to jewelry building in addition, the place intricate styles and flawless finishes are essential for building significant-value parts. in the end, vacuum stress casting delivers the mandatory Management and precision website to meet the demanding requirements of these industries. As evidenced by merchandise much like the TAKJ-VC-W offered at https://taeantech.com/products/takj-vc-w, these equipment are specially made to cater to your precision necessary by vacuum stress casting processes.

In summary, vacuum force casting devices are indispensable instruments for reaching high precision and remarkable high quality in steel casting. The combination of vacuum natural environment and controlled force gets rid of frequent casting defects, improves content Attributes, and makes certain dimensional accuracy. For industries demanding the best levels of performance and reliability, purchasing vacuum tension casting technologies is not merely a choice but a requirement. evaluate the precise needs of one's software and investigate the varied vacuum stress casting methods available to unlock new prospects in metal casting and elevate the standard of your ultimate items.

Alana "Honey Boo Boo" Thompson Then & Now!

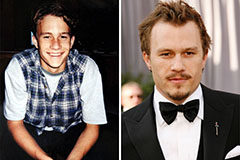

Alana "Honey Boo Boo" Thompson Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!